Swedish Loom Restoration at Gammelgarden

July 7, 2023 3 Comments

Scandia, Minnesota is the site of the first Swedish settlement in Minnesota. Gammelgarden Museum in Scandia helps preserve this history through its programs, exhibits, and five historic buildings while celebrating the stories of all immigrants and their communities.

On the second floor of the Välkommen Hus (shown above), there is an old floor loom. The loom was made in Sweden by a father with the intention that it would go to America with his daughter and her husband who would leave shortly after their wedding. The year 1879 is painted on the loom.

The daughter and her family used the loom in northern Minnesota until 1962 when it was sold at auction to Myrabelle Lange Sommerfeld. Myrabelle used the loom for rug weaving until early 1999. Everyone she knew had one of her rugs! In 2003, the loom was generously donated to Gammelgarden by Myrabelle’s daughter, April Sommerfeld Corgärd.

While the loom has been admired by countless visitors, it needed some minor repairs to be functional again. The Gammelgarden staff put an ad in the classified section of the Weavers Guild of Minnesota website, asking for assistance.

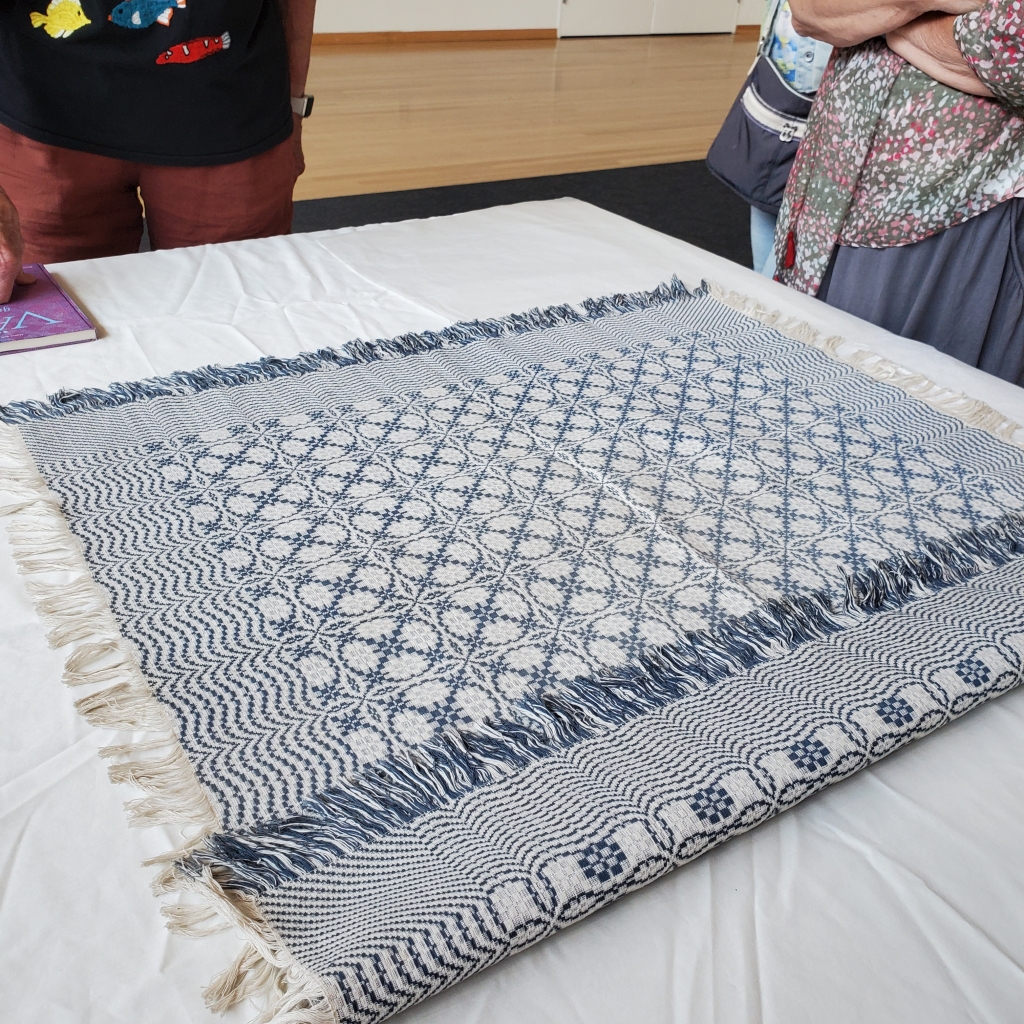

Judy Larson, a member of the Scandinavian Weavers, happily volunteered. “It was an opportunity to see an old Swedish loom and visit Gammelgarden,” she explains. “The counterbalance loom is dated 1879 and was carved by a father for his daughter who was leaving for America. The side supports have some lovely wood carvings. As the loom was used by generations of weavers, there were changes made. A worm gear was added in place of the back brake. The string heddles were changed to metal heddles, and the shafts and treadles were held with nylon cords secured by wires, instead of knots. The front brake was still original and is exactly like the one on my great grandmother’s Swedish loom.”

Judy got to work restoring the loom: “I reset the worm gear rotation wheel to engage correctly, and then got the treadle cords and heddle cords to pull evenly and adjusted the reed height to get a better shed. The loom was now functional, and weaving could happen.”

Judy returned two weeks later with fabric weft prepared and started weaving a blue gingham placemat: “I showed three volunteers how to weave on the loom, and even got some visitors to try throwing the shuttle across. The video was made, and a short description of weaving terms is posted by the loom. There is a QR code for visitors to access the video and see the 144-year-old loom in action.” Judy donated more weft fabric so weaving can continue.

Judy also restored an old tape loom at Gammelgarden so it is now functional. Thanks to her generosity and expertise, visitors to Gammelgarden can try their hand at weaving, which played such an important role in the daily lives of Swedish immigrants.

Less than an hour from the Twin Cities, Gammelgarden is well worth a visit! Be sure to try out the loom while you are there. To learn more, visit their website at gammelgarden.org (link below)